The Rheem UMC 117 manual is a comprehensive guide for installing, operating, and maintaining the Rheem tankless water heater controller․ It provides essential safety precautions, installation steps, and troubleshooting tips to ensure efficient and safe system operation․ Available in PDF format, the manual offers easy access to critical information for optimal performance and user safety․ The UMC-117 remote control enables precise temperature adjustments and maintenance access, making it a vital component for managing your water heater system effectively․

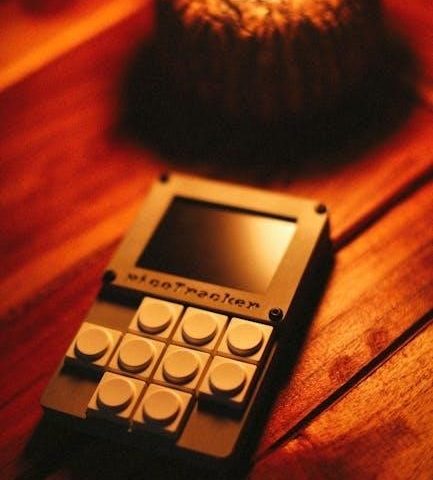

1․1 Overview of the Rheem UMC 117 Controller

The Rheem UMC 117 is a sophisticated digital remote control designed for use with Rheem tankless water heater systems․ It provides users with precise temperature control, ranging from 85°F to 140°F (29°C to 60°C) for residential applications, and up to 180°F (82°C) for heavy-duty models․ The controller allows for easy adjustments and access to maintenance information, ensuring optimal system performance․ It supports connection of up to three remote controls, offering flexibility and centralized control for multiple units․ The UMC 117 is compatible with various Rheem tankless water heater models, making it a versatile component for both residential and commercial settings․ Its user-friendly interface and advanced features enable efficient management of water heating systems while adhering to safety and performance standards․ This controller is integral to Rheem’s innovative solutions, providing a reliable and efficient way to monitor and adjust water heater settings․

1․2 Importance of the Manual for Safe and Efficient Use

The Rheem UMC 117 manual is crucial for ensuring the safe and efficient operation of the tankless water heater system․ It provides detailed guidelines for installation, startup, and daily operation, helping users avoid potential hazards and optimize performance․ The manual outlines essential safety precautions, such as emergency shutdown procedures, gas leak detection, and pressure relief valve setup, to prevent system damage and ensure user safety․ Additionally, it offers troubleshooting tips and maintenance information, enabling users to identify and resolve issues quickly․ By following the manual, users can comply with industry standards, ensure proper venting, and maintain the system’s efficiency․ The manual serves as an indispensable resource for both installers and end-users, providing clear instructions to prevent suboptimal functionality and safety risks․ Regular adherence to the manual’s guidelines ensures the system operates reliably and meets all necessary certifications and performance expectations․

Installation Guidelines

The Rheem UMC 117 manual provides critical installation guidelines, including pre-installation checks, venting requirements, and gas connection procedures․ Proper setup ensures safe and efficient system operation and efficiency․

2․1 Pre-Installation Checks and Requirements

Before installing the Rheem UMC 117 controller, ensure all pre-installation checks are completed to guarantee safe and proper system operation․ Verify that the gas pressure matches the heater’s specifications and that all electrical connections comply with local codes․ Inspect the venting system for damage or blockages and ensure it meets CSA certification standards․ Check that the pressure relief valve is correctly installed and rated for domestic water pressure․ Confirm the remote control cable is securely connected, and the system is properly grounded․ Ensure the installation location allows for adequate clearance from combustibles, with a minimum of 1/2 inch side-to-side clearance․ Review local regulations and manufacturer guidelines to ensure compliance․ Properly align and connect the vent termination kit, ensuring it is configured according to the manual’s instructions․ Address any issues before proceeding with the installation to prevent potential hazards and ensure optimal performance․ Always refer to the manual for detailed specifications and requirements․

2․2 Step-by-Step Installation Process

Begin by carefully unpacking the Rheem UMC 117 controller and its components, ensuring all parts are included and undamaged․ Locate the installation site, ensuring it meets clearance requirements, such as 1/2 inch from combustibles․ Drill a 1 to 1․5-inch hole for the controller cable and securely connect the 18 AWG cable to the water heater․ Mount the remote control in a convenient location, ensuring it is level and accessible․ Connect the pressure relief valve, ensuring it is ASME-certified and set to relieve at or below 150 psi, with proper threading and placement within 6 inches of the hot water outlet․ Install the vent termination kit according to CSA standards, using approved materials like PVC or CPVC, and ensure proper slope and alignment․ Connect the gas lines, verifying correct pressure and ensuring no leaks․ Follow the manual’s instructions to configure the DIP switch settings, if necessary, to match your application needs․ Finally, power on the system and test all components to ensure proper operation․ Refer to the manual for specific wiring and connection details to complete the installation safely and efficiently․

2․3 Venting System Requirements and Safety

Proper venting is critical for safe and efficient operation of the Rheem UMC 117 system․ The venting system must comply with CSA certification standards (ANSI Z21․10․3) for gas water heaters․ Use approved materials such as PVC, CPVC, or polypropylene for venting, ensuring proper slope and support․ The vent termination kit must be installed according to manufacturer specifications and local codes, with clearances of at least 1/2 inch from combustibles; Regular inspections are required to check for blockages, damage, or misalignment․ Improper venting can lead to safety hazards, including carbon monoxide buildup․ Ensure the venting system is configured correctly to prevent backdrafting and maintain proper airflow․ Annual inspections by a qualified technician are recommended to ensure compliance with safety standards and prevent potential hazards․ Refer to the manual for detailed venting requirements and safety guidelines to ensure a safe and efficient installation․

Features and Specifications of the Rheem UMC 117

The Rheem UMC 117 supports temperature adjustments up to 140F for residential use and 180F for heavy-duty models․ It offers a BTU range of 11,000 to 599,700 and flow rates up to 16․1 GPM, ensuring compatibility with various Rheem tankless water heater models․ The controller allows connection of up to three remote controls for centralized system management and includes error codes for troubleshooting․ It supports manifold configurations for up to three units, making it versatile for residential and light commercial applications․ These features ensure precise temperature control, efficient performance, and flexibility for different water heating needs․

3․1 Temperature Control and Adjustment Options

The Rheem UMC 117 offers advanced temperature control and adjustment options, allowing users to set precise water temperatures for optimal comfort and efficiency․ Residential users can adjust temperatures from 85°F to 140°F (29°C to 60°C) using the remote control, while heavy-duty models can reach up to 180°F (82°C) by configuring the DIP switch, a task recommended for qualified personnel․ The controller ensures temperature consistency, preventing scalding risks by maintaining safe levels, such as 120°F (49°C) for general use; Higher temperature settings require careful adherence to manual guidelines to ensure safety standards are met․ This versatility in temperature control makes the UMC 117 suitable for various applications, from residential to light commercial settings, providing users with the flexibility to tailor their water heating needs while adhering to safety and performance standards․

3․2 Compatibility with Rheem Tankless Water Heater Models

The Rheem UMC 117 controller is designed to be compatible with a wide range of Rheem tankless water heater models, ensuring seamless integration and enhanced performance․ It works efficiently with high-efficiency models such as the RTGH-C95DVLN and RTGH-CM95DVLN, among others, making it a versatile solution for both residential and light commercial applications․ The controller supports manifold configurations, allowing connection to up to three tankless water heaters, which is ideal for larger systems or multi-unit setups․ This compatibility ensures users can maximize their water heating capabilities while maintaining precise temperature control and system efficiency․ By supporting multiple Rheem models, the UMC-117 offers flexibility and convenience, enabling users to tailor their water heating systems to meet specific needs without compromising on performance or safety․ This broad compatibility makes the UMC-117 a reliable and adaptable choice for various water heating configurations․

3․3 Technical Specifications and Performance Capabilities

The Rheem UMC 117 controller is engineered to deliver high-performance capabilities, supporting a wide range of applications․ It operates within a BTU range of 11,000 to 599,700, ensuring flexibility for both residential and light commercial use․ The controller supports flow rates of up to 16․1 GPM at a 70°F temperature rise and 11․3 GPM at a 100°F rise, catering to varying water heating demands․ Temperature settings can be adjusted between 85°F (29°C) and 140°F (60°C) for residential models, with heavy-duty models capable of reaching up to 180°F (82°C)․ The UMC-117 enables precise temperature control and efficient system operation, making it suitable for multiple tankless water heater configurations․ Its advanced design ensures compatibility with Rheem’s high-efficiency models, such as the RTGH-C95DVLN and RTGH-CM95DVLN, while maintaining safety and performance standards․ These technical specifications make the UMC-117 a reliable and efficient solution for diverse water heating needs․

Operating the Rheem UMC 117

The Rheem UMC 117 operates efficiently with clear startup procedures and temperature management․ Daily operation involves easy adjustments via the remote control, while accessing maintenance information ensures optimal performance and longevity․

4․1 Startup and Initial Setup Procedures

The Rheem UMC 117 manual outlines clear startup and initial setup procedures to ensure safe and efficient operation․ Begin by connecting the remote control to the water heater, ensuring proper installation of the 18 AWG controller cable․ Verify that all gas and power connections are secure and meet local regulations․ Perform a system check to ensure all components function correctly․ Set the initial temperature using the remote control, typically starting at 120°F for safe operation․ Refer to the manual for specific DIP switch configurations if higher temperatures are required․ Always follow the manufacturer’s guidelines for startup to avoid potential hazards․ Proper initialization ensures optimal performance and longevity of the system․ If issues arise, consult the troubleshooting section for solutions․ Adhere to safety precautions outlined in the manual to ensure a smooth and secure startup process․

4․2 Daily Operation and Temperature Management

Daily operation of the Rheem UMC 117 involves straightforward temperature management using the remote control․ Users can easily adjust the water temperature within a range of 85°F to 140°F (29°C to 60°C) for residential applications, ensuring optimal comfort and energy efficiency․ The remote control provides precise control, allowing users to set their preferred temperature conveniently․ For heavier-duty models, temperatures can reach up to 180°F (82°C) with proper DIP switch configurations, though this should only be done by qualified personnel․ Regular monitoring of temperature settings is essential to prevent scalding risks, especially in households with vulnerable individuals․ The UMC-117 also allows access to maintenance information, enabling users to track system performance and address potential issues promptly․ By following the manual’s guidelines, users can ensure safe and efficient daily operation while maintaining desired water temperatures for various applications․

4․3 Accessing Maintenance Information

The Rheem UMC 117 manual provides clear instructions for accessing maintenance information, ensuring users can monitor and service their water heater system effectively․ Through the remote control, users can view error codes and system status updates, enabling quick identification of potential issues․ The manual includes detailed explanations of error codes, such as code 12 for temperature control malfunctions and code 4 for gas-related problems, guiding users through troubleshooting steps․ Regular maintenance checks, such as verifying gas connections and flow rates, are also outlined to prevent malfunctions․ Additionally, the UMC-117 allows users to access critical performance data, including BTU levels and temperature settings, ensuring optimal system operation․ By following the manual’s maintenance guidelines, users can extend the lifespan of their water heater and maintain its efficiency and safety․ Proper maintenance practices are essential for ensuring reliable performance and adhering to manufacturer recommendations;

Safety Precautions and Emergency Procedures

The Rheem UMC 117 manual outlines essential safety precautions, including emergency shutdown procedures, gas leak detection, and pressure relief valve setup․ These guidelines ensure safe operation and prevent potential hazards or system damage․ Always follow the manual’s instructions to maintain safety and efficiency․ Proper adherence to these procedures is crucial for protecting users and ensuring reliable system performance․ By following the manual, users can address emergencies effectively and minimize risks associated with gas leaks or system malfunctions․ Regular inspections and maintenance, as detailed in the manual, further enhance safety and operational integrity․ Adhering to these precautions ensures compliance with industry standards and manufacturer recommendations, safeguarding both the user and the system․ The manual’s clear instructions provide peace of mind and ensure optimal functionality under all operating conditions․ Safety is a top priority, and the UMC-117 manual delivers comprehensive guidance to achieve it․

5․1 Emergency Shutdown Procedures

In case of an emergency, the Rheem UMC 117 manual provides clear shutdown procedures to ensure safety․ Users should immediately turn off the power supply and gas valves to halt operation․ The manual instructs not to ignite appliances or use electrical switches during a gas leak․ Instead, open windows for ventilation and follow specific leak detection steps outlined in the manual․ For emergency situations, the UMC-117 manual recommends consulting Section 4 for detailed shutdown instructions․ Proper shutdown procedures are critical to maintaining user safety and system integrity․ The manual emphasizes adhering to these steps to prevent accidents or system damage․ By following the guidelines, users can effectively handle unexpected situations and ensure the system’s safe operation․ Always refer to the manual for specific instructions on emergency shutdown to address potential hazards promptly and correctly․ This ensures the safety of both the user and the system, aligning with Rheem’s commitment to reliability and safety standards․ Proper emergency procedures are essential for maintaining trust and performance in the UMC-117 controller․ Follow the manual’s instructions without deviation to secure optimal outcomes in critical situations․

5․2 Gas Leak Detection and Response

If a gas leak is detected, immediate action is required to ensure safety․ The Rheem UMC 117 manual instructs users to avoid igniting appliances or using electrical switches, as this could trigger an explosion․ Instead, the power and gas supply to the water heater should be turned off immediately․ Windows should be opened to ventilate the area, and the manual provides specific steps for gas leak detection and response․ Proper installation and regular maintenance are crucial to minimize the risk of gas leaks․ Users are advised to follow the manual’s guidelines for ensuring the system’s safe operation․ Regular inspections by qualified personnel can help identify potential issues before they escalate․ By adhering to the manual’s instructions, users can address gas leaks effectively, preventing hazardous situations and ensuring the system’s reliability․ Always prioritize safety and follow the recommended procedures for gas leak detection and response to maintain a secure environment․ The UMC-117 manual serves as a vital resource for handling such critical situations responsibly․

5․3 Pressure Relief Valve Setup and Safety

The Rheem UMC 117 manual emphasizes the importance of correctly setting up and maintaining the pressure relief valve to ensure system safety and efficiency․ The valve must be ASME-certified, relieve at or below 150 psi, and have a minimum capacity of 199,000 BTU/hr․ It should be installed within 6 inches of the DHW hot outlet and feature 3/4 NPT threads․ The valve must be rated for domestic water pressure to prevent malfunctions․ Proper installation by a qualified technician is crucial to avoid risks such as scalding or system damage․ Regular inspections and testing are recommended to ensure the valve functions correctly․ The manual provides detailed guidelines for installation, maintenance, and testing to comply with safety standards․ Adhering to these instructions ensures the pressure relief valve operates effectively, protecting both the user and the system from potential hazards․ Always refer to the manual for specific setup and safety procedures to maintain a safe and reliable water heating system․ Proper setup is essential for optimal performance and user safety․

Troubleshooting and Maintenance

The Rheem UMC 117 manual provides detailed troubleshooting guides, including error codes like 12 and 4, and maintenance tips to ensure optimal performance and longevity of the water heater system․

6․1 Common Issues and Error Codes

The Rheem UMC 117 manual identifies common issues and error codes to help users diagnose and resolve problems efficiently․ Error code 12 typically indicates a temperature control malfunction, while error code 4 suggests gas-related issues such as improper connections or sensor functionality․ The manual provides clear guidelines for addressing these errors, including checking gas lines, verifying sensor operation, and ensuring proper remote control linkage․ Regular maintenance, such as inspecting flow rates and BTU levels, can prevent recurring issues․ Users are advised to consult the manual for specific troubleshooting steps and reset procedures to restore functionality quickly․ By following the manual’s recommendations, users can identify and resolve common problems, ensuring optimal performance and extending the system’s lifespan․ Proper care and adherence to troubleshooting guidelines are essential for maintaining safety and efficiency․

6․2 Troubleshooting Steps and Solutions

The Rheem UMC 117 manual provides detailed troubleshooting steps to address common issues․ For error code 12, which indicates a temperature control malfunction, users should check sensor connections and ensure proper system calibration․ Error code 4, related to gas issues, requires verifying gas valve operation and ensuring correct gas pressure․ The manual recommends checking remote control linkage and ensuring all connections are secure․ Users should also review flow rates and BTU levels to identify imbalances․ Regular maintenance, such as cleaning sensors and inspecting venting systems, can prevent recurring problems․ The manual advises resetting the system after addressing issues and testing operation to confirm resolution․ By following these structured steps, users can efficiently diagnose and resolve issues, ensuring optimal performance and safety․ Proper troubleshooting ensures the system operates within recommended parameters, minimizing downtime and extending its lifespan․

6․3 Regular Maintenance and Inspection Tips

Regular maintenance is crucial for ensuring the Rheem UMC 117 operates efficiently and safely․ Users should inspect the venting system annually to ensure proper alignment, no blockages, and compliance with CSA standards․ Clean or replace filters as needed to maintain optimal airflow․ Check gas pressure and connections regularly to prevent leaks or malfunctions․ Inspect the condenser and heat exchanger for dirt or corrosion and clean them if necessary․ Ensure all electrical connections are secure and free from damage․ Additionally, verify that the pressure relief valve is functioning correctly and meets ASME certification standards․ Schedule annual professional inspections to address potential issues before they escalate․ By following these maintenance tips, users can extend the system’s lifespan, prevent common issues, and ensure safe, efficient operation․ Regular upkeep also helps maintain compliance with industry standards and certifications, ensuring reliable performance over time․

Compliance and Certifications

The Rheem UMC 117 meets CSA certification standards for venting and is a member of AHRI, ensuring compliance with safety and efficiency regulations․ It adheres to federal and local codes and performance expectations․

7․1 CSA Certification and Venting Standards

The Rheem UMC 117 manual emphasizes compliance with CSA certification standards for venting systems, ensuring safe and reliable operation of the tankless water heater․ The system is designed to meet ANI Z21․10․3 standards for gas water heaters, guaranteeing adherence to safety and performance requirements․ Proper venting is crucial, and the manual specifies the use of approved materials such as PVC, CPVC, or polypropylene for venting, ensuring durability and resistance to corrosion․ Additionally, the vent termination kits must comply with CSA standards to prevent blockages and ensure proper exhaust flow․ The UMC-117 system is compatible with high-efficiency models and can support venting configurations for up to 10 units, making it a versatile solution for residential and commercial applications․ Regular inspections by qualified technicians are recommended to maintain compliance and ensure the venting system operates safely and efficiently․ This adherence to CSA standards underscores Rheem’s commitment to providing reliable and safe water heating solutions․

7․2 AHRI Membership and Industry Compliance

As a full member of the Air-Conditioning, Heating, & Refrigeration Institute (AHRI), Rheem ensures the UMC 117 controller meets stringent industry standards for performance, safety, and efficiency․ AHRI membership underscores Rheem’s commitment to producing high-quality products that align with global sustainability and innovation goals․ The UMC 117 is designed to comply with federal, state, and local regulations, ensuring seamless integration into various residential and commercial applications․ By adhering to AHRI standards, Rheem guarantees that the UMC 117 operates efficiently, reducing energy consumption while maintaining optimal water heating performance․ This compliance not only enhances system reliability but also supports Rheem’s leadership in the HVAC industry․ The UMC 117’s alignment with AHRI standards is a testament to Rheem’s dedication to delivering cutting-edge, eco-friendly solutions that meet the evolving needs of consumers and professionals alike, ensuring long-term satisfaction and operational excellence․